How to measure the v belt length?

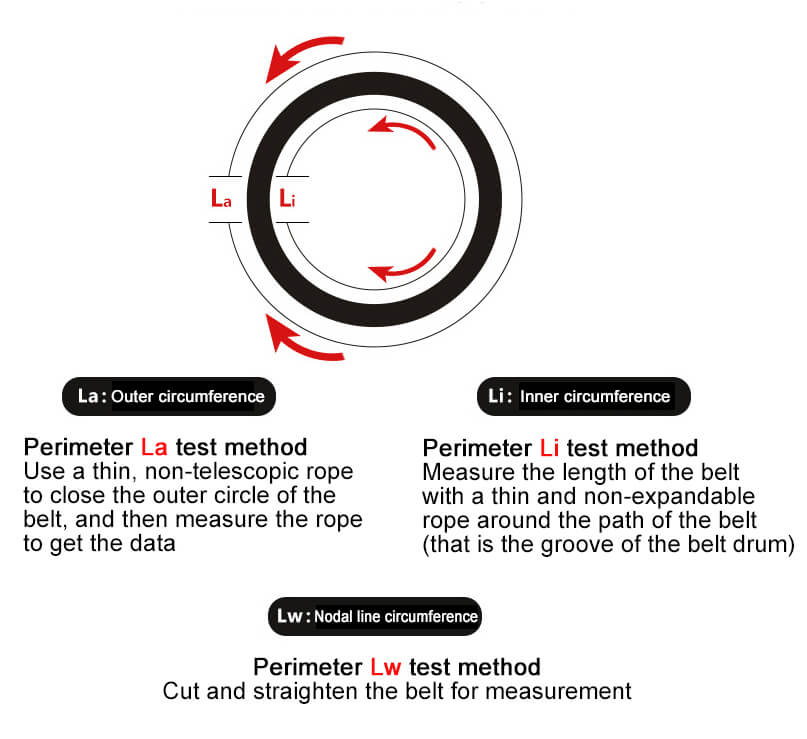

Outside Belt Length:

The outside length of a v belt is usually measured with a tape under no tension. Its validity is questionable since some belts have an arched top whereas others are flat. This would give different readings for the two belts. It can be used only as an approximation.

Inside Belt Length:

The inside length is measured with flat pulleys (not v-pulleys) and a tape measure. As with the outside length, the inside length varies with the manufacturer. This length should not be used.

Note: As clarified with Gates, if you know the diameter of the flat pulleys and the center distance between them, then you can calculate belt length. This will be equal to half the circumference of each pulley plus double the length between the shaft centres.

Belt Pitch (Datum) Length:

The pitch length of a belt is the length at the pitch diameter of the sheaves being used. Classical industrial belts are specified in terms of pitch length. The pitch length is obtained by adding the pitch circumference of one sheave (pulley) to twice the center distance between two equal diameter sheaves (pulleys) at a specified tension.

The belt pitch length is normally the length at the belt pitch line. This line is generally located at the neutral axis near the cord line and varies with cross section and construction. The pitch of the belt and sheave is actually a theoretical point that relates to the more accurate, reliable, and useable effective diameter and effective length.

This datum system defines specific sheave (pulley) and belt dimensions previously known as the pitch system for classical belts and sheaves. What were previously identified as pitch diameter or pitch length are now known as datum diameter or datum length. These are the new catalog identifiers which allow all belt and sheave manufacturers and users to use the same nomenclature.

Belt Effective Length:

The effective length of a belt is the length about the effective outside diameter of a sheave at a specified tension. The effective outside diameter of a sheave is measured where the groove top width is a dimension as specified by RMA, ASAE or SAE standards. The effective length is obtained by adding the effective outside circumference of one sheave (pulley) to twice the center distance between the two standard measuring sheaves (pulleys) at the standard measuring tension.

English

English Espanol

Espanol Pусский

Pусский Chinese

Chinese